Business

Mobile & Display Products

To use

Advantage

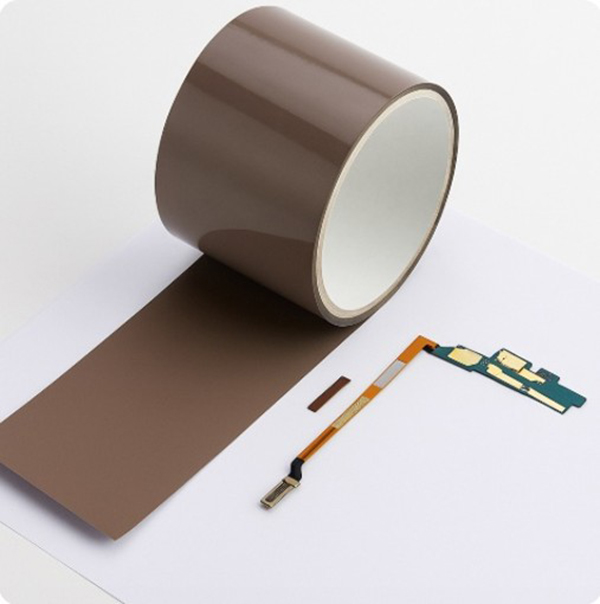

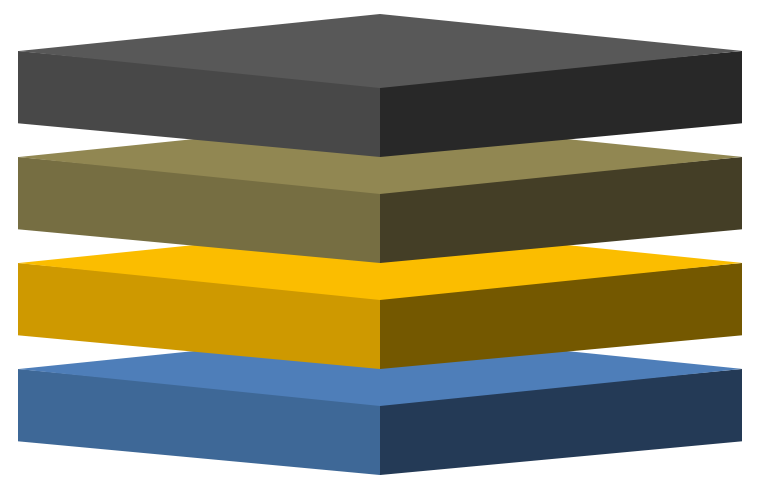

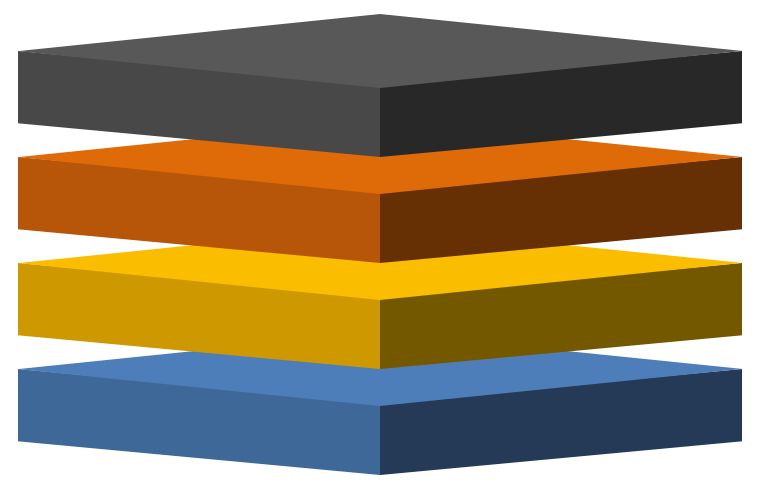

Product Structure

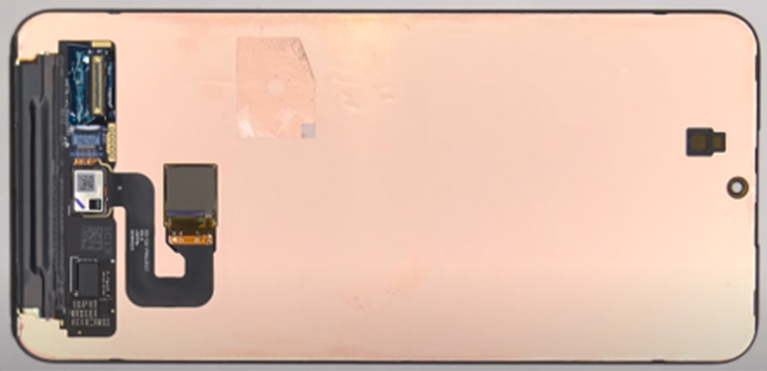

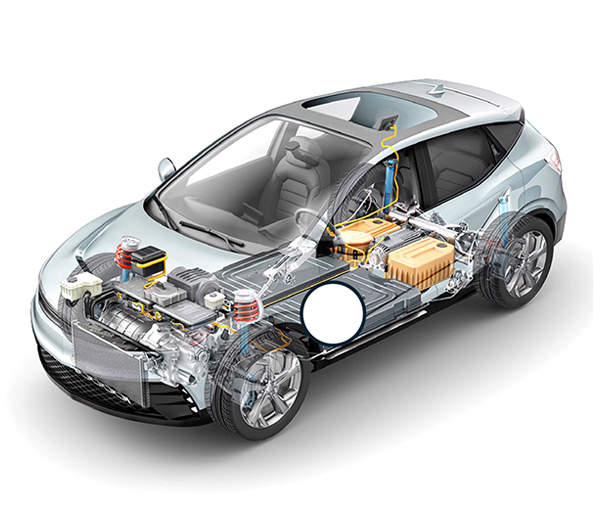

Application Fields

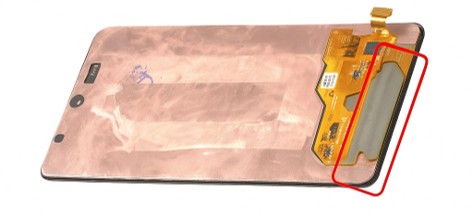

※ OLED module applied, heat dissipation metal tape(Cu)

To use

Advantage

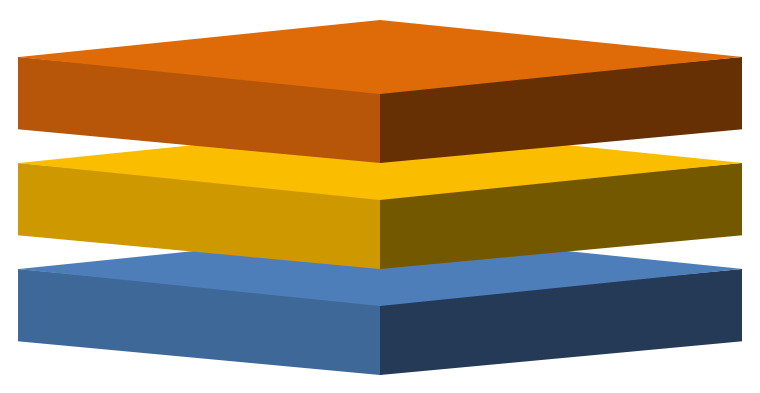

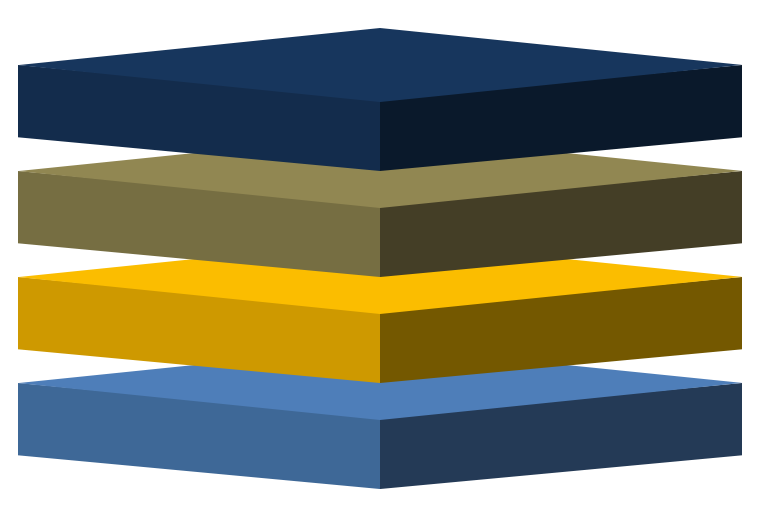

Product Structure

Application Fields

※ Conductive fabric double-sided tape for PBA

To use

Advantage

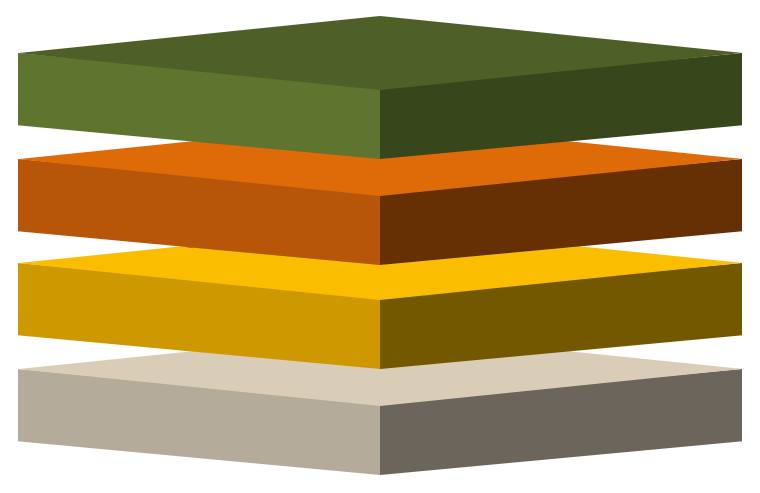

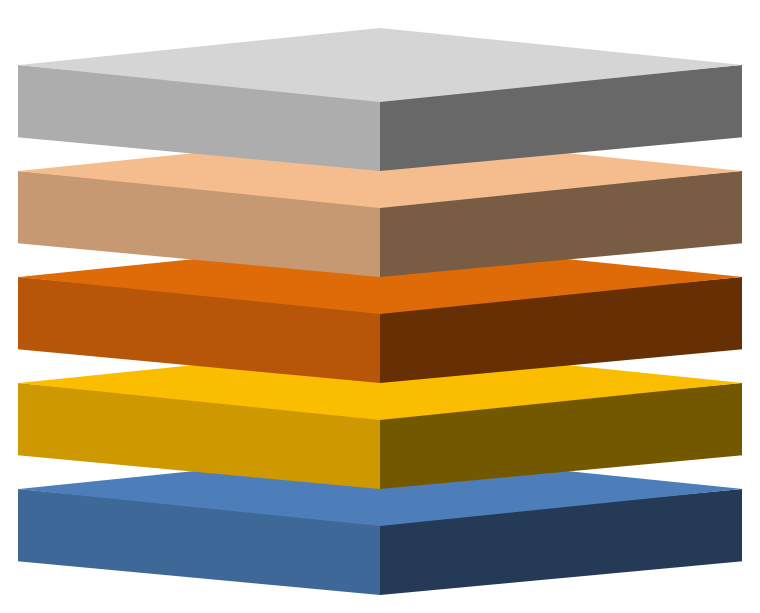

Product Structure

Application Fields

To use

Advantage

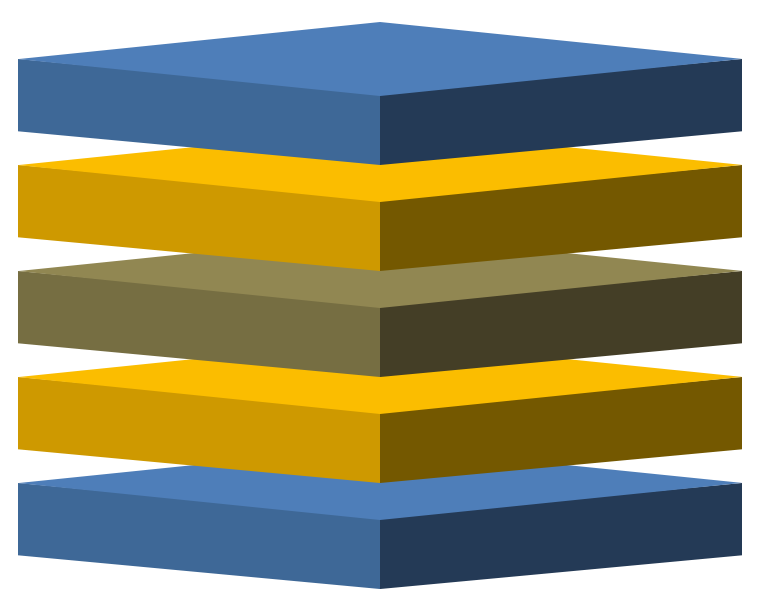

Product Structure

Changes in HR tape adhesion by temperature section

Application Fields

To use

Advantage

Product Structure

Please slide the table to check.

| Classification | Foam (1 Layer) |

PET integrated type (2 Layer) |

Adhesion integrated way (3 Layer) |

Skin integrated type (2 Layer) |

Light-shielding integrated type (3 Layer) |

|---|---|---|---|---|---|

| Structure |  |

|

|

|

|

| PU Foam (Cell Pad) | PU Foam | PU Foam | PU Foam | Black PET | |

| PET | PU Foam | ||||

| PET | Adhesion(PSA) | Skin | Skin | ||

| Thickness (mm) | 0.1 ~ 3.0 | 0.15 ~ 3.0 | 0.1 ~ 4.5 | 0.1 ~ 3.0 | 0.2 ~ 3.0 |

| Application Fields | Mass production of secondary batteries is in progress | Mass production of smartphones is in progress | Mass production of foldable phones is in progress | Mass production of monitors/TVs is in progress | Mass production of monitors/TVs is in progress |